Backflow Testing Services by Litteken Plumbing

Backflow testing is one of the most important preventative measures for maintaining the safety and cleanliness of your water supply. Without it, contaminants like fertilizer, sewage, and chemicals can flow backward into your home or commercial property’s clean water system—posing serious health risks and potential liability issues. At Litteken Plumbing, we offer professional backflow testing and inspection services throughout the Metro East to ensure your plumbing system is secure and up to code.

With over 25 years of experience, our licensed technicians are certified in backflow prevention and testing. Whether you’re required to submit an annual test report for your local municipality or want peace of mind about your water quality, we make the process easy, reliable, and affordable.

Who Needs Backflow Testing?

Backflow testing is required by law in many municipalities and is particularly important for properties that have cross-connections with potentially hazardous systems.

Required Testing Applies To:

- Commercial properties with irrigation or fire protection systems

- Multi-family housing complexes

- Restaurants and food service facilities

- Industrial facilities

- Properties with private wells

- Homes with sprinkler systems or pool plumbing

Even if not mandated by law, regular backflow testing is strongly recommended to avoid health risks and water contamination.

Our Backflow Testing Process

Litteken Plumbing follows a precise and certified process to ensure your backflow prevention device meets safety standards and local regulations.

Step 1: Site Evaluation – We assess your plumbing system layout and location of the backflow prevention device.

Step 2: Device Inspection – Our technician checks for visible signs of wear, damage, or tampering.

Step 3: Pressure Testing – Using calibrated gauges, we measure the pressure differential and check for valve performance and sealing.

Step 4: System Flush (if needed) – We flush out debris or buildup that could compromise the device.

Step 5: Test Report Submission – Upon completion, we file your test results with the appropriate municipality or water authority.

Step 6: Documentation – You’ll receive a full report for your records, and we’ll remind you when your next test is due.

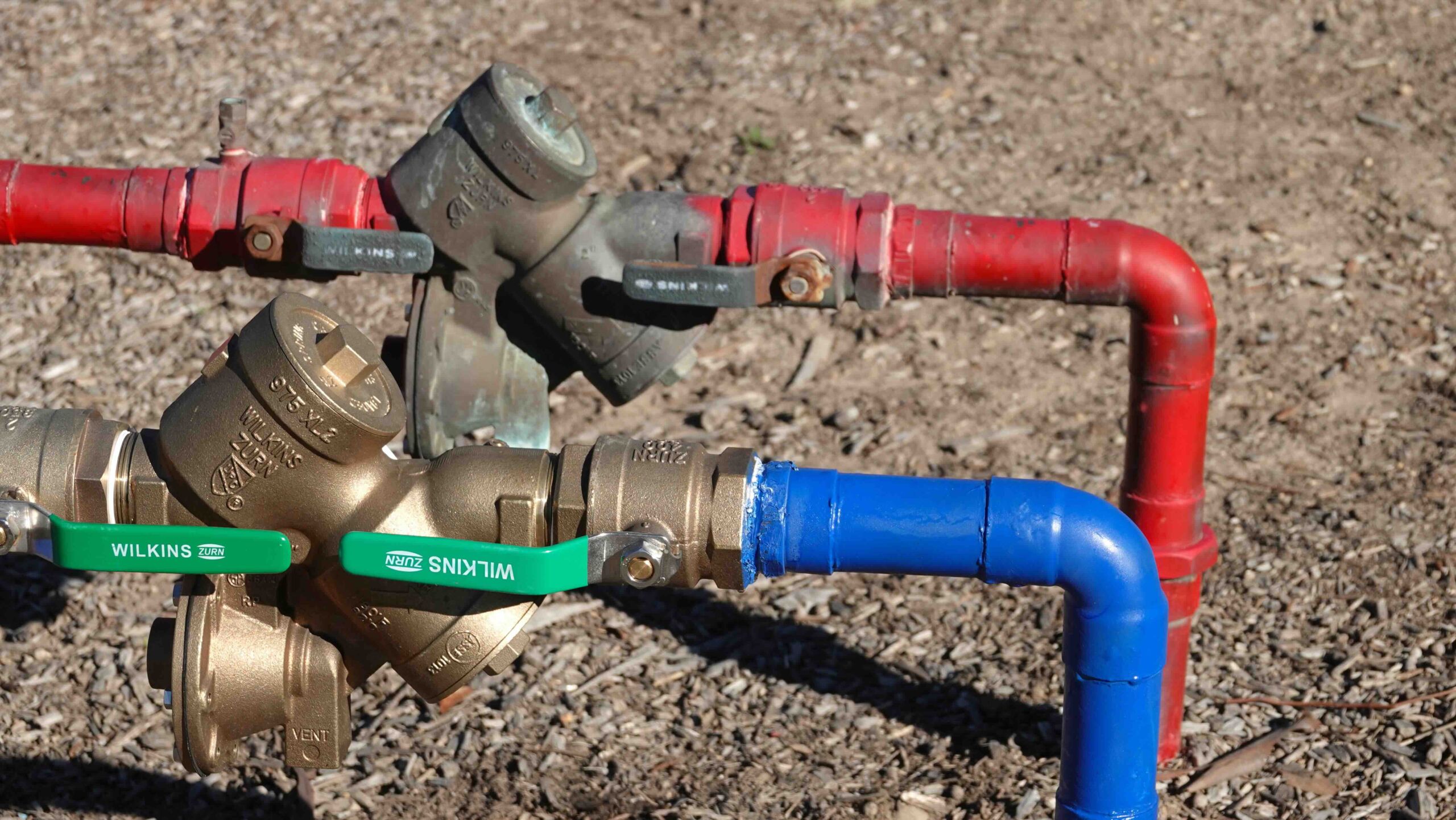

We test all major types of devices, including reduced pressure zone (RPZ) assemblies, double check valve assemblies (DCVA), and pressure vacuum breakers (PVB).

Types of Backflow Prevention Devices We Test

Backflow prevention devices are designed to protect your drinking water supply from contamination. Each type serves a specific function depending on your system configuration.

Reduced Pressure Zone (RPZ) Assemblies

RPZ devices offer the highest level of protection against backflow and are typically installed in high-risk environments such as industrial facilities, hospitals, and commercial kitchens. These devices contain two independent check valves separated by a pressure-monitored chamber. If either valve fails, the chamber vents water to the ground, preventing contamination.

Double Check Valve Assemblies (DCVA)

DCVAs are commonly used in low- to medium-hazard situations such as residential irrigation systems or fire lines. This device features two spring-loaded check valves that work together to prevent backflow. While not as protective as RPZ units, they are easier to install and maintain in areas where the contamination risk is lower.

Pressure Vacuum Breakers (PVB)

PVBs are designed for systems that may be subject to back-siphonage, such as lawn sprinklers. These devices consist of a check valve and an air inlet valve that opens if pressure drops. While effective for irrigation setups, PVBs are not suited for high-hazard applications or where backpressure may occur.

Atmospheric Vacuum Breakers (AVB)

AVBs are basic devices typically installed on individual hose bibs or wall-mounted faucets. They prevent water from being siphoned back into the system by allowing air to enter when pressure drops. AVBs must be placed downstream of shut-off valves and require one device per fixture.

Understanding Illinois EPA and Local Compliance Codes

In Illinois, the Environmental Protection Agency (IEPA) mandates strict backflow prevention policies to protect public water supplies from contamination. The Illinois Plumbing Code and Cross-Connection Control regulations outline which properties need devices, how often they must be tested, and what standards must be met.

Annual Testing

Most devices must be tested and reported annually by a certified tester.

Cross-Connection Surveys

Municipalities are required to survey all service connections for potential contamination risks.

Recordkeeping

Device owners must retain test records for at least five years and provide them upon request.

Certified Testers

Only individuals with Illinois EPA-approved certifications are authorized to perform official testing.

In addition to state regulations, local jurisdictions often have supplementary requirements—such as additional inspection intervals or approved device types.

At Litteken Plumbing, we stay informed about all applicable local ordinances and water district policies. We serve as a liaison between property owners and public health departments, ensuring that your property stays compliant and your water stays clean.

Consequences of Backflow Testing Non-Compliance

Failing to comply with backflow testing requirements isn’t just a code violation—it can have serious and expensive consequences. Municipalities throughout Illinois are stepping up enforcement efforts to ensure public water systems remain protected.

Potential Penalties and Consequences:

- Fines and Penalties: Many jurisdictions issue escalating fines for missed testing deadlines or incomplete documentation. These can range from $100 to several thousand dollars depending on the offense.

- Water Shutoffs: Local water providers may disconnect service until a certified test has been completed and approved. This can halt operations for commercial facilities.

- Health Code Violations: Businesses, especially restaurants and medical facilities, may face health department violations or be forced to close temporarily.

- Contaminated Water Supply: The most serious risk is allowing contaminants to enter your potable water supply. This can lead to illness, property damage, and costly remediation.

- Liability Lawsuits: If negligence results in harm to residents, employees, or customers, the property owner may be held legally liable for damages.

How Backflow Prevention Devices Are Installed

Backflow device installation depends on the type of system and local code requirements. At Litteken Plumbing, we follow industry best practices and manufacturer specifications for every installation.

Our Installation Process Includes:

1. Site Survey: We evaluate your plumbing configuration, location risks, and existing system connections.

2. Code Compliance Review: We determine what type of backflow prevention device is required by your municipality and the appropriate location.

3. Installation Planning: Our team identifies optimal placement that allows accessibility, weather protection, and protection from flooding.

4. Device Mounting and Connection: The device is installed inline on the water supply line. Piping is secured, valves are fitted, and connections are leak-tested.

5. Initial Testing: A certified tester ensures the new device is functioning correctly and documents the results.

6. Reporting and Permitting: We handle all required documentation and submit final reports to local authorities or water districts.

Whether retrofitting an old line or planning a new build, we install backflow devices with long-term performance and ease of maintenance in mind.

Backflow Repair and Replacement Services

If your backflow prevention device fails testing, we offer prompt and affordable repair or replacement services to restore compliance.

Common Issues We Fix:

- Leaking test ports

- Damaged check valves

- Broken or stuck shut-off valves

- Debris inside the assembly

We carry replacement parts for all major manufacturers and can usually complete repairs on the same day as your inspection.

When replacement is necessary, we’ll help you choose a compliant, long-lasting device and install it with minimal disruption.

Preventive Maintenance for Backflow Devices

Just like other components in your plumbing system, backflow preventers benefit from regular maintenance.

Maintenance Includes:

- Flushing debris buildup

- Cleaning valve seats and springs

- Lubricating internal seals

- Testing pressure zones to detect slow failures

Routine care helps extend the life of your device and reduces the risk of surprise failures or emergency replacements.

Residential & Commercial Backflow Testing

We offer comprehensive backflow testing for both residential and commercial clients. While the testing process is similar, commercial systems often include more complex configurations and stricter code requirements.

Residential Systems May Include:

- Lawn irrigation lines

- Outdoor hose attachments

- Swimming pools or spas

- Secondary water supplies or wells

Commercial Systems May Include:

- Multiple fire suppression lines

- Boiler feeds

- Food prep or processing areas

- Water-cooled HVAC units

- Medical and lab water systemsWarehouses and industrial spaces

Our team is equipped to test and service backflow devices on all property types—from single-family homes to large-scale industrial facilities.

Why Choose Litteken Plumbing for Backflow Testing Services?

When it comes to protecting your property’s water supply, experience matters. At Litteken Plumbing, we bring over 25 years of hands-on expertise to every backflow testing service we provide. Our team is fully certified, licensed, and trained to handle backflow prevention devices of all types—ensuring your system is safe, compliant, and functioning as it should.

- Certified Backflow Testers – We meet all state and municipal requirements to provide official testing and documentation.

- Local Code Knowledge – We stay current on local ordinances and work directly with city officials to streamline compliance.

- Accurate, Reliable Reporting – We handle all paperwork, submit reports on your behalf, and keep detailed records for your peace of mind.

- Fast, Convenient Service – We respect your time with flexible scheduling and prompt turnaround.

Whether you’re a homeowner maintaining a lawn irrigation system or a business managing multiple devices, we make backflow testing simple and stress-free.

Frequently Asked Questions About Backflow testing

Most municipalities require annual testing. Check with your local water provider or give us a call for local guidelines.

Typically 20–30 minutes, depending on the type of device and accessibility.

If the device is located outside and easily accessible, you don’t need to be present. For interior devices, access will be required.

We’ll explain the issue, recommend repair or replacement options, and offer a quote. Once fixed, we’ll retest to ensure compliance.

Not unless you’re a licensed and certified tester. Municipalities only accept test results from qualified professionals.

Yes—without it, contaminants could enter your drinking water. It’s a critical public health safeguard.

Prices vary by device type and location. Call us for a free quote tailored to your property.

Serving Homeowners and Businesses Across the Metro East

We proudly provide backflow testing, repair, and maintenance services in:

- Trenton IL

- Bartelso, IL

- Lebanon, IL

- Germantown, IL

- Highland, IL

- Carlyle, IL

- Greenville, IL

- St. Jacob, IL

- And nearby communities

Our licensed plumbers are familiar with the plumbing systems, codes, and needs of the Metro East region, so you can trust Litteken to do the job right.

Schedule Your Backflow Test Today

Don’t let a missed test deadline or faulty device put your water supply—and health—at risk. Litteken Plumbing makes backflow testing simple and stress-free.

Our certified team handles everything from inspections and repairs to documentation and compliance—all at a fair price.

Contact us today to schedule your backflow test and protect your water quality with confidence.

Litteken Plumbing – Your Metro East Experts for Certified Backflow Testing.